Posted

6th August 2021

Company News

Commodity costs continue to spike week on week throughout 2021. As construction, e-commerce and other industries roar with life, in the wake of COVID-19, demand outstrips supply on essential raw materials. Several raw materials are now at an all-time high, with further price rises forecast for the rest of 2021.

Why are raw material prices increasing?Raw material prices have skyrocketed throughout 2021 as lockdowns ease and industries start back up again. Many of these same raw materials are used in construction, car manufacturing, e-commerce and more.With industries looking to recover from 2020’s disruption, companies have added pressure to stock back up on raw material stores they may have let dwindle during 2020.For us, we’ve already seen the price of natural fibres used in our Clinell wipes hit an all-time high.

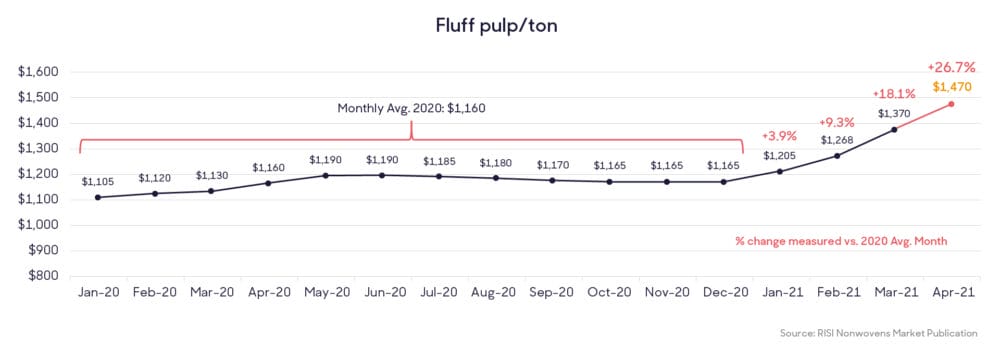

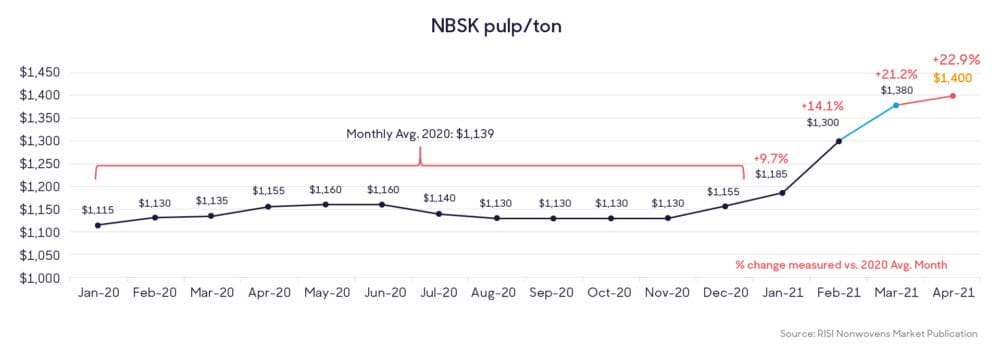

One of the first raw materials to spike in price was wood pulp. In early 2020, with the onset of the pandemic looming, toilet paper became an unlikely symbol of safety and security. An avalanche of anxious shoppers hurried to secure the same product at the same time, overwhelming supply chains.

The sudden surge caused a knock-on effect all the way up the supply chain, with the price of wood pulp spiking almost immediately. Because millions of products across hundreds of industries rely on wood pulp, price increases made their way down other supply chains as well.

What we see now is, in some ways, a repeat of that initial toilet paper shortage. But this time, it’s on a global, industrial scale. In fact, the price of wood pulp is now significantly higher than it was in early 2020 (with forecasts predicting it will continue to rise).

Click graph to enlarge

What raw materials have increased prices?

Timber, natural fibres, plastics and resins have all seen significant increases throughout 2021 (along with many other raw materials). What started with individual commodities has spread to affect entire supply chains.

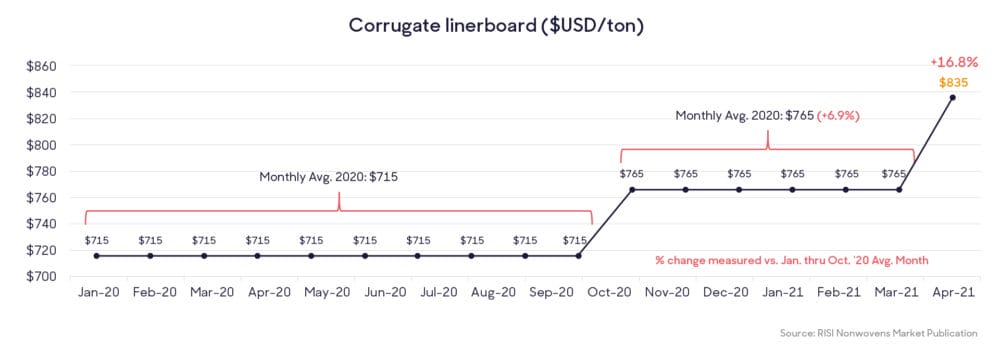

Even packaging materials have been affected. With massive shifts to online shopping and e-commerce causing price rises on corrugated cardboard. All those extra individual deliveries have a profound effect on the rest of the supply chain.

Click graph to enlarge

We saw some of this volatility back in 2020, during the first stages of the pandemic. Unfortunately, in 2021, the price increases we’re facing are even more drastic and even more widespread.

Natural fibres used in Clinell and other GAMA Healthcare products, that were relatively stable throughout 2020, have seen huge increases in 2021.

Click graph to enlarge

Impact of the shipping crisis

We’ve talked about the ongoing shipping crisis before in our cost of shipping article. Unprecedented demand, coupled with a raft of challenges facing the shipping industry, has seen the cost of transporting goods increased by nearly 700%.

Many companies, including us at GAMA Healthcare, have looked to increase production outside South-East Asia to minimise the cost impact of the crisis. Whilst that may alleviate some pressure transporting the final product, raw materials are still very much a global market.

Shipping costs are exceptionally significant in the overall cost of raw materials (as raw materials are more bulky and lower value relative to finished products). That means the price of raw materials is likely to remain exceptionally high whilst the shipping price continues.

How is GAMA Healthcare dealing with raw material price increases?

Throughout the pandemic, we’ve been absorbing increased production costs wherever possible. We’re an infection prevention company, and we want to make sure our infection prevention products are available to the hospitals, businesses and people who need them.

Unfortunately, we’re now seeing costs in our supply chain soar to 10 times what they were just a year ago. Like many businesses, we’re doing everything we can in the face of enormous cost pressures.

- We’re absorbing costs wherever we can.

Everything we do is driven by our purpose: to help prevent infections to save and improve lives. That means making sure we offer the most effective products at the most affordable price point possible. We will continue to absorb costs whenever and wherever we can to support that purpose.

- We’re bringing on new partners.

We’re working with new partners throughout our supply chain, increasing our resilience in a volatile marketplace.

- We’re strengthening our Supply Chain team.

We’ve expanded our Supply Chain Department, creating new roles to directly manage production and transport costs over the short- and long-term.

- We’re accelerating our cost-improvement projects.

We’re diverting our time and resources towards projects that will help us improve our production costs for 2021 and beyond.

- We’re continuing to innovate.

Infection prevention is a constantly evolving field. We’re driving innovation to make our solutions more effective, easier to use and continually cost-effective.

2020 brought us all challenges. As an infection prevention company, we rose to meet them. 2021 brings even more. We’ll continue to do everything we can to support the infection prevention community.

SHARE THIS ARTICLE

Tags

Latest News

Norovirus: Understanding its transmission and prevention in the UK

Introduction Norovirus is recognised as the leading cause of viral gastroenteritis…

Clean Between to Reduce Healthcare-Associated Infections

Healthcare-associated infections (HAIs) are a significant concern for healthcare facilities…

Mpox: emergence of a new threat

A new threat related to mpox is emerging, in the…

Wiping away infections – the CLEEN way!

Cleaning shared medical equipment with a disinfectant wipe at least…